1 Nkọwa na ihe kpatara mmebi n'okpuru ala

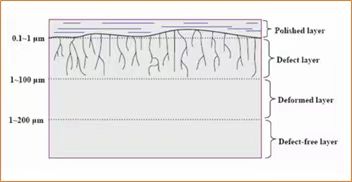

A na-akpọkarị mmebi nke sub-elu nke ngwa anya ngwa anya (SSD, sub-surface damage) na ngwa anya dị elu dị ka sistemụ laser siri ike na igwe lithography, na ịdị adị ya na-egbochi nhazi ikpeazụ nke ngwa anya ma na-emetụtakwa eserese ahụ. arụmọrụ nke ngwa anya usoro, ya mere, ọ kwesịrị ka a na-akwụ ụgwọ zuru ezu nlebara anya.A na-amakarị mmebi nke dị n'okpuru ala site na mgbawa dị n'ime elu nke mmewere na ọkwa nrụgide dị n'ime, bụ nke a na-akpata site na ụfọdụ nbibi na nrụrụ nke ihe mejupụtara ihe dị n'akụkụ elu dị nso.E gosipụtara ụdị mmebi nke subsurface dị ka ndị a: oyi akwa dị n'elu bụ akwa sedimenti na-egbuke egbuke, mgbe ahụ, oyi akwa ntụpọ na-akpata nrụgide bụ oyi akwa nke ala, na ihe oyi akwa na-enweghị mmebi bụ oyi akwa dị n'ime.N'ime ha, oyi akwa ntụpọ mgbawa na oyi akwa deformation bụ mmebi nke dị n'okpuru ala.

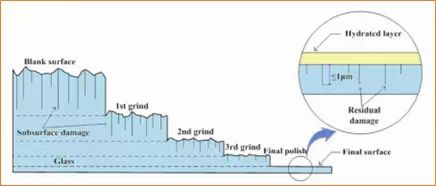

Ụdị mmebi n'okpuru ala nke ngwa anya

Ngwa anya mmiri nke ihe onwunwe bụ n'ozuzu iko, ceramik na ndị ọzọ siri ike na kenkuwa ihe, na mmalite nhazi ogbo nke components, mkpa na-aga site-egwe ọka ịkpụzi, ezi egweri na ike polishing Filiks, na ndị a Filiks, n'ibu egweri na chemical mmeghachi omume adị. ma gwuo egwu.The abrasive ma ọ bụ abrasive ngwá ọrụ na kọntaktị na elu nke mmewere nwere àgwà nke uneven urughuru size, na ike nke ọ bụla kọntaktị ebe n'elu nke mmewere na-adịghị edo, otú convex na concave oyi akwa na esịtidem mgbape oyi akwa ga- a ga-emepụta n'elu iko.Ihe dị na oyi akwa gbawara agbawa bụ ihe mebiri emebi n'oge a na-egweri, ma ọ daghị n'elu, ya mere a ga-emepụta mmebi nke sub-surface.Ma ọ bụ abrasive egweri nke rụrụ ahụ ma ọ bụ CNC egweri, a onu ga-guzobere n'elu ihe.A na-egosi n'ezie mmetụta nke mmebi okpuru ala n'ọnụọgụ a:

Mmebi nke dị n'okpuru ala

2 Ụzọ nha mmebi nke ala

Ebe ọ bụ na enweghị ike ileghara mmebi nke dị n'okpuru ala anya, ndị na-emepụta ngwa anya ga-ejikwa ya nke ọma.Iji chịkwaa ya nke ọma, ọ dị mkpa iji chọpụta n'ụzọ ziri ezi na ịchọpụta oke mmebi nke subsurface n'elu akụkụ ahụ, ebe ọ bụ na mmalite nke narị afọ gara aga, ndị mmadụ emepụtawo ụzọ dịgasị iche iche iji tụọ na nyochaa nha. nke mmebi nke subsurface nke akụrụngwa, dị ka usoro nke ogo mmetụta na ngwa anya, enwere ike kewaa ya ụzọ abụọ: nha na-emebi emebi na nha na-adịghị emebi emebi (nnwale na-adịghị emebi emebi).

Usoro nha nke na-emebi emebi, dị ka aha ahụ na-egosi, ọ dị mkpa ịgbanwe ọdịdị elu nke ngwa anya, ka enwere ike ikpughe mmebi nke sub-elu nke na-adịghị mfe ịhụ, wee jiri microscope na ngwa ndị ọzọ na-ahụ anya. Usoro nha, usoro a na-ewekarị oge, mana nsonaazụ nha ya bụ nke a pụrụ ịdabere na ya na nke ziri ezi.Ụzọ nha ndị na-adịghị emebi emebi, nke na-adịghị emebi emebi ọzọ n'elu akụkụ ahụ, na-eji ọkụ, ụda, ma ọ bụ ebili mmiri electromagnetic ndị ọzọ chọpụta oyi akwa mmebi nke dị n'okpuru ala, ma jiri ọnụọgụ mgbanwe nke ihe onwunwe ha na-eme na oyi akwa iji chọpụta nha nke na SSD, ndị dị otú ahụ ụzọ ndị dịtụ adaba na ngwa ngwa, ma na-abụkarị a qualitative chọpụtara.Dị ka nkewa nke a, ụzọ nchọpụta ugbu a maka mmebi nke sub-elu ka egosiri na foto dị n'okpuru:

Nhazi na nchịkọta nke ụzọ nchọpụta mmebi nke ala

Nkọwa nkenke nke usoro nha ndị a bụ:

A. Ụzọ mbibi

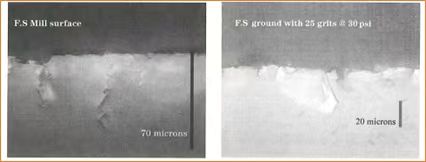

a) Usoro nchacha

Tupu ọdịdị nke magnetorheological polishing, ndị ọrụ anya na-ejikarị Taper polishing nyochaa mmebi dị n'okpuru ala nke ngwa anya, ya bụ, na-egbutu elu anya n'akụkụ akụkụ oblique iji mepụta elu dị n'ime ya, wee na-ehichapụ elu ahụ.A na-ekwenyekarị na ihicha ihe agaghị eme ka mmebi nke mbụ dị n'okpuru ala ka njọ.A ga-ekpughe ihe mgbawa nke oyi akwa SSD nke ọma site na corrosion nke imi mmiri na reagents.Enwere ike tụọ omimi, ogologo na ozi ndị ọzọ nke oyi akwa mmebi nke dị n'okpuru ala site na nlele anya nke elu ahụ nwere mmasị mgbe imikpuchara ya.Mgbe e mesịrị, ndị ọkà mmụta sayensị chepụtara usoro ịgba bọọlụ (Ball dimpling), nke bụ iji ihe na-eme ka ọkpụkpụ na-egbuke egbuke na-egbuke egbuke n'elu ala ma egwerie ya, na-atụba olulu, omimi nke olulu kwesịrị ịdị omimi dị ka o kwere mee, nke mere na nyocha. nke akụkụ nke olulu nwere ike nweta ozi mmebi nke subsurface nke mbụ elu.

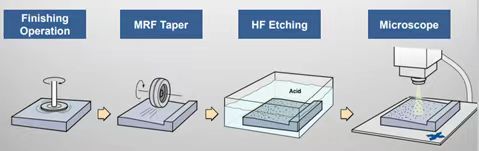

Ụzọ ndị a na-ahụkarị maka ịchọpụta mmebi n'okpuru ala nke ihe anya

Magnetorheological polishing (MRF) bụ usoro na-eji eriri mmiri magnetik na-ekpocha ihe ndị dị na anya, nke dị iche na polishing asphalt/polyurethane omenala.N'ime usoro polishing omenala, ngwá ọrụ polishing na-arụkarị ike dị ukwuu n'elu anya anya, ebe Mr Polishing na-ewepụ anya anya na ntụziaka tangential, n'ihi ya, Mr Polishing anaghị agbanwe àgwà mmebi mbụ nke sub-surface mebiri nke elu anya.Ya mere, enwere ike iji Mr Polishing mee ka oghere dị n'elu anya anya.Mgbe ahụ, a na-enyocha ebe a na-egbuke egbuke iji nyochaa nha nke mmebi dị n'okpuru ala nke mbụ ngwa anya.

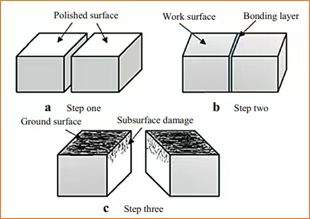

A na-ejikwa usoro a iji nwalee mmebi n'okpuru ala.N'ezie, họrọ ihe nlele square nke nwere otu ọdịdị na ihe onwunwe, kpochaa akụkụ abụọ nke ihe nlele ahụ, wee jiri nrapado na-ejikọta akụkụ abụọ a na-egbuke egbuke nke sample ọnụ, wee gwerie akụkụ nke abụọ ahụ ọnụ n'otu oge. oge.Mgbe egwerichara, a na-eji reagents kemịkalụ kewapụ ihe atụ square abụọ ahụ.Enwere ike nyochaa nha mmebi nke dị n'okpuru ala nke ogbo egweri na-akpata site na iji microscope were lelee elu ahụ ekpochapụrụ iche.Usoro nhazi usoro nke usoro a bụ nke a:

Eserese atụmatụ nke nchọpụta mmebi nke dị n'okpuru ala site na usoro nrapado

Usoro a nwere ụfọdụ njedebe.N'ihi na e nwere elu nnyapade, ọnọdụ nke nnyapade elu nwere ike ọ gaghị egosipụta n'ụzọ zuru ezu mmebi nke subsurface n'ime ihe ahụ mgbe ọ gwuchara, ya mere nsonaazụ nha nwere ike igosipụta ọnọdụ SSD ruo n'ókè ụfọdụ.

a) Chemical etching

Usoro a na-eji ọgwụ kemịkalụ dabara adaba iji mebie oyi akwa mebiri emebi nke elu anya.Mgbe emechara usoro mbuze ahụ, a na-enyocha mmebi nke dị n'okpuru ala site na ọdịdị elu na ịdị njọ nke ihe mejupụtara ya na mgbanwe index nke oke mbuze.Ihe reagents nke a na-ejikarị eme ihe bụ hydrofluoric acid (HF), ammonium hydrogen fluoride (NH4HF) na ihe ndị ọzọ na-emebi emebi.

b) Usoro nke ngalaba

A na-ekesa ihe nlele ahụ, a na-eji microscope eletrọn na-enyocha ihe iji hụ nha mmebi nke dị n'okpuru ala.

c) Usoro ihe eji agba agba

N'ihi na elu oyi akwa nke ala ngwa anya element nwere ọnụ ọgụgụ buru ibu nke microcracks, e ji esiji ákwà ndị nwere ike na-etolite a agba iche na ngwa anya mkpụrụ ma ọ bụ iche na mkpụrụ nwere ike pịa n'ime ihe.Ọ bụrụ na mkpụrụ ahụ nwere ihe gbara ọchịchịrị, enwere ike iji akwa fluorescent mee ihe.Enwere ike ịlele mmebi nke dị n'okpuru ala n'ụzọ anya ma ọ bụ na eletrọnịkị.N'ihi na mgbawa na-adịkarị mma na n'ime ihe ahụ, mgbe omimi ntinye nke ntinye agba agba ezughị, ọ nwere ike ọ gaghị anọchi anya ịdị omimi nke microcrack.Iji nweta omimi mgbape ahụ n'ụzọ ziri ezi dịka o kwere mee, a tụpụtara ọtụtụ ụzọ maka ịcha akwa: n'ibu prepressing na oyi isostatic pressing, na iji eletrọn probe microanalysis (EPMA) iji chọpụta akara nke agba na obere mkpokọta.

B, ụzọ na-adịghị emebi emebi

a) Usoro atụmatụ

Usoro ntule tumadi na-eme atụmatụ omimi nke mmebi nke sub-elu dị ka nha nha nke ihe abrasive si dị na nha elu nke ihe ahụ.Ndị na-eme nchọpụta na-eji ọnụ ọgụgụ dị ukwuu nke ule iji guzobe mmekọrịta kwekọrọ n'etiti nha nha nke ihe abrasive na omimi nke mmebi nke sub-surface, yana tebụl kwekọrọ n'etiti nha nke ihe na-adịghị mma nke akụkụ ahụ na sub-. mmebi elu.Enwere ike ime atụmatụ mmebi nke dị n'okpuru ala nke elu ihe dị ugbu a site na iji akwụkwọ ozi ha.

b) Tomography nke jikọrọ anya (OCT)

Tomography njikọ anya, ụkpụrụ bụ isi nke ya bụ nnyonye anya Michelson, na-enyocha ozi a tụrụ site na nrịbama nnyonye anya nke ọkụ abụọ.A na-ejikarị usoro a na-elele anụ ahụ dị ndụ ma na-enye tomography nke akụkụ dị n'okpuru ala nke anụ ahụ.Mgbe a na-eji usoro OCT hụ mmebi nke ala dị n'okpuru ala nke elu anya, a ga-atụlerịrị ihe nrịbama index nke ihe atụ tụrụ iji nweta omimi mgbape n'ezie.Enwere ike ịkọ usoro a na-achọpụta ntụpọ na omimi nke 500μm yana mkpebi kwụ ọtọ karịa 20μm.Otú ọ dị, mgbe a na-eji ya maka nchọpụta SSD nke ngwa anya, ìhè na-egosipụta site na oyi akwa SSD adịghị ike, ya mere ọ na-esiri ike ịmepụta nnyonye anya.Na mgbakwunye, ịgbasa n'elu ga-emetụtakwa nsonaazụ nha, na nha nha kwesịrị ka emeziwanye ya.

c) Usoro ịgbasa laser

A na-amụkwa nke ọma n'ọgba aghara laser n'elu elu fotometric, na-eji ihe ndị na-agbasasị nke laser iji chọpụta oke mmebi nke dị n'okpuru ala.Ndị a na-ahụkarị gụnyere mkpokọta ntughari microscopy (TIRM), microscopy confocal laser scanning (CLSM), na intersecting polarization confocal microscopy (CPCM).cross-polarization confocal microscopy, wdg.

d) Na-enyocha microscope acoustic

Nyocha acoustic microscopy (SAM), dị ka usoro nchọpụta ultrasonic, bụ usoro nnwale na-adịghị emebi emebi nke a na-ejikarị achọpụta ntụpọ dị n'ime.A na-ejikarị usoro a tụọ ihe nlele na elu dị larịị.Mgbe elu nke ihe nlele ahụ siri ike, a ga-ebelata nha nha n'ihi mmetụta nke ebili mmiri gbasasịrị n'elu.

3 Ụzọ njikwa mmebi n'okpuru ala

Ọ bụ ihe mgbaru ọsọ kachasị anyị iji chịkwaa nke ọma mmebi n'okpuru ala nke ngwa anya ma nweta ihe ndị na-ewepụ SSDS kpamkpam.N'okpuru nkịtị ọnọdụ, omimi nke sub-elu mmebi bụ hà nhata nke abrasive urughuru size, nta nke urughuru size nke abrasive, ndị shallower na sub-elu mmebi, ya mere, site mbenata granularity nke egweri, na n'ụzọ zuru ezu. egweri, ị nwere ike nke ọma melite ogo sub-elu mmebi.E gosipụtara eserese nhazi nke njikwa mmebi n'okpuru ala na nkebi na foto dị n'okpuru:

A na-achịkwa mmebi nke dị n'okpuru ala na nkebi

Nzọụkwụ mbụ nke ichikota ga-ewepụ kpamkpam mmebi nke subsurface na mbara ala ma mepụta ọhụụ ọhụrụ na nke a, na mgbe ahụ na nke abụọ nke igwe ihe, ọ dị mkpa iji wepụ SSD emepụtara na nke mbụ ma mepụta mmebi ọhụrụ n'okpuru ala. ọzọ, nhazi n'aka, na ịchịkwa urughuru size na ịdị ọcha nke abrasive, na n'ikpeazụ nweta anya ngwa anya elu.Nke a bụkwa usoro nhazi nke mmepụta ihe anya na-agbaso ruo ọtụtụ narị afọ.

Na mgbakwunye, mgbe usoro egweri gasịrị, ịchịkọta elu nke akụkụ ahụ nwere ike wepụ mmebi nke sub-elu nke ọma, si otú a na-eme ka ọdịdị elu dị elu ma melite arụmọrụ nhazi.

Kpọtụrụ:

Email:jasmine@pliroptics.com ;

Ekwentị/Whatsapp/Wechat:86 19013265659

webụ:www.pliroptics.com

Tinye: Ụlọ 1, No.1558, okporo ụzọ ọgụgụ isi, qingbaijiang, chengdu, sichuan, china

Oge nzipu: Eprel 18-2024